Fused Silica Brick

MOQ<5TONS

Description

Fused silica bricks the thermal expansion rate of spe- cial silica bricks is lower than that of high-quality silica bricks used in general glass kilns and coke oven.They will not expand or crack after long-term use.

Features

1. Strong thermal shock resistance, stable chemical properties, SiO2 content greater than 99%, excellent corrosion resistance and acid resistance.

2. Low Fe 2O3 content less than 0.1%, for products (such as glass liquid, etc.)

3. Low flux index (Al2O3+2R2O) less than 0.3%, corrosion resistance, good high temperature resistance.

4. Fused silica bricks thermal expansion coefficient is close to zero, and no expansion joints need to be reserved during repair, which increases the tightness of the masonry.

5. It is not easy to adhere to carbon under high temperature and long-term use, and has good resistance to erosion by molten steel.

6. Excellent thermal stability, the product will not explode during hot repair, and the repair work can be carried out directly at high temperature without stopping the furnace.

7. After repair (hot repair), there will be no peeling and other phenomena, and it is safe and reliable for long-term use.

8. No long-term furnace baking is required after masonry; no preheating is required.

Products Parameters

|

Brand Properties |

JGZ96 |

JGZ95 |

JGZ94 |

JSG98 |

|

|

Chemical Composition (%) |

SiO₂ |

96 |

95 |

94 |

98.5 |

|

Fe₂O₃ |

1.0 |

1.2 |

1.4 |

0.1 |

|

|

AlO₃+CaO+TiO₂ |

一 |

一 |

一 |

0.23 |

|

|

Apparent Porosity (%) |

22 |

22 |

22 |

16 |

|

|

True Density (g/cm³) |

2.34 |

2.35 |

2.35 |

2.31 |

|

|

Cold Crushing Strength (MPa) |

30 |

30 |

30 |

40 |

|

|

@0.2MPa Refractoriness Under Load (℃) |

1660 |

1650 |

1640 |

1680 |

|

|

Bulk Density (g/cm³) |

1.85 |

1.83 |

1.81 |

1.85 |

|

|

1100℃(times) Thermal Shock resistance water cool |

一 |

一 |

一 |

30 |

|

|

Main Applications |

Hot-blast Furnace Coke Oven Glass Kiln |

||||

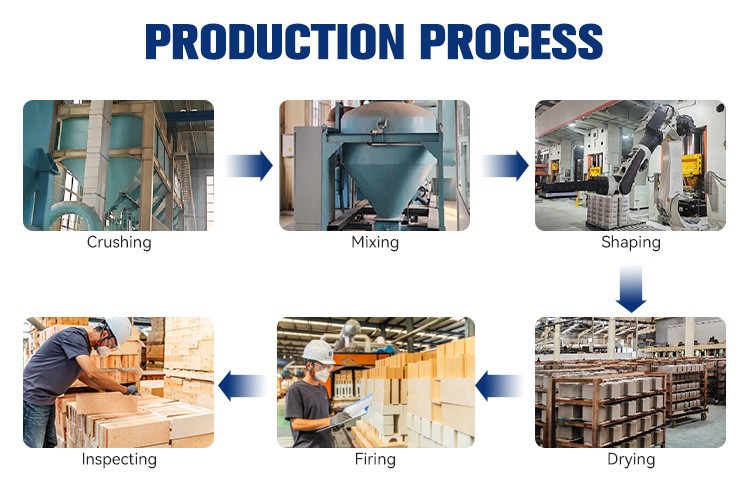

Production Process

1. Selection of particle composition

The looseness and sintering of the siliceous blank during heating depends on the nature and number of coarse and fine particle sizes in the particle composition. When using a brick blank composed of fine particles, it is beneficial to reduce shrinkage during firing, reduce cracks and volume changes in the brick body, improve the product rate, and increase the content of tridymite in the product, but the fine particles of the mud will also increase the porosity of fused silica bricks. The critical particle size of silica bricks is generally 2-3mm.

2. Molding

The characteristics of silica brick molding are reflected in the molding characteristics of silica brick blanks and the complex appearance and quality differences of silica bricks. Siliceous blanks are hard, low-bonding and low-plasticity barren materials, so their compression and compacting properties are low. The molding performance of siliceous blanks is affected by their particle composition, moisture and additives. Adjusting these components can improve the molding performance of blanks. For blanks of any composition, increasing the molding pressure can increase the density of zero-expansion silica bricks. In order to obtain dense bricks, the molding pressure should not be less than 100-150MPa.

3. Firing

Silica bricks undergo phase change and large volume changes during the firing process. In addition, the amount of molten liquid formed by the bricks at the firing temperature is relatively small (about 10% or less), making it much more difficult to fire than other refractory materials. The firing of zero-expansion silica bricks has nothing to do with the series of physical and chemical changes that occur in the bricks during the firing process, the number and properties of the participants, the size of the body, and the characteristics of the firing kiln.

Products Application

Fused silica bricks are widely used in metallurgy, chemical industry and light industry. In metallurgy, they are mainly used as immersion nozzles in continuous casting and carbonization chambers in coke ovens. In chemical industry, they are mainly used as the top of glass melting furnaces. Zero expansion silica bricks are easy to make into large blocks due to their small expansion rate, high thermal stability and high compressive strength, and their surface is smooth and free of carbon deposition.

Hot Tags: fused silica brick, China fused silica brick manufacturers, suppliers, factory, standard refractory brick, clay brick firing kiln clay brick, Fused Cast Alpha Beta Al2O3 Firebrick, furnace insulation Ceramic Fiber Blanket, refractory bauxite, Zirconia Ceramic Blanket

Previous

Anti Corrosion Carbon BrickYou Might Also Like

Send Inquiry